High-Pressure Seat Seals for Ball Valves

The ball valve seat plays a critical role in sealing the process fluid and distributing the seating stress evenly across the contact surface. In petrochemical and energy applications, even a minor leak can be environmentally devastating and cause costly downtime. To address these challenges, high-pressure seat seals are designed with superior sealing integrity, durability, and adaptability to extreme service conditions.

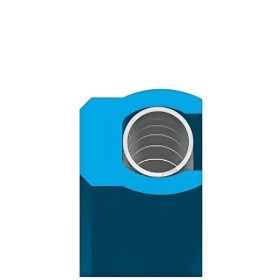

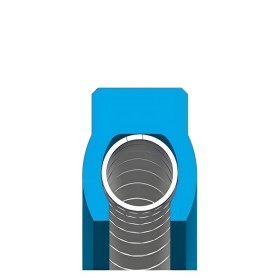

Seal Design and Structure

Seal Jacket: Polymer-based material, most commonly PTFE. Fillers can be customized depending on temperature and media requirements. PTFE offers low friction, wide temperature stability, and broad chemical resistance.

Spring Energizer: Metal spring element, available in helical, cantilever, or canted coil designs. The spring ensures continuous sealing force, compensating for wear, dimensional variations, and pressure fluctuations.

The seal geometry (lip design) and spring type are selected based on application conditions such as dynamic vs. static sealing, internal vs. external pressure, and the expected pressure/temperature range.

Performance in High-Pressure Applications

Helical springs provide the steepest load curve and the highest sealing force per unit deflection, making them particularly effective for static face seals and cryogenic high-load applications.

The compressible stroke of the spring-jacket combination enables self-compensation for seal lip wear and tolerance variations in the groove.

The use of advanced PTFE composites and corrosion-resistant springs ensures long service life even in aggressive petrochemical environments.

Advantages

Withstands high pressure and low temperatures

Reliable in medium- to high-pressure environments

Excellent sealing performance with reduced leakage risk

Customizable designs available to meet customer-specific applications

Working Conditions

Temperature range: –100℃ to +180℃

Pressure: ≤400 bar

Mediums: Gas, water, hydrocarbons

Applications

High-pressure ball valve seat seals are widely applied in industries where safety and sealing reliability are paramount:

Petrochemical plants

Oil & gas upstream and downstream

LNG transfer systems

Refining and chemical processing

Power generation and utilities

Industrial water and steam systems