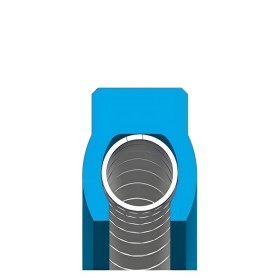

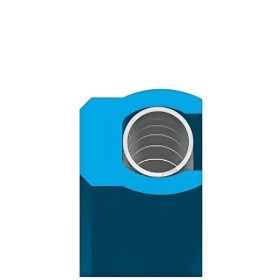

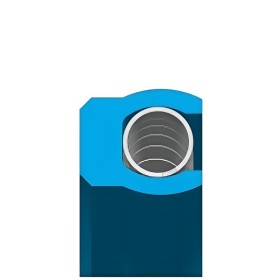

Helical Spring Stem Seals for Ball Valves

Helical spring stem seals are advanced spring energized Teflon seals specially designed for ball valve applications. The sealing mechanism relies on the elastic force of the helical spring combined with system pressure, which pushes the sealing lip firmly against the valve stem or metal surface. This ensures reliable, long-lasting sealing performance even under the most demanding conditions.

Compared to conventional elastomer seals, spring energized seals overcome issues of rubber softening, swelling, and wear, significantly extending the service life of cryogenic and high-pressure ball valves.

Material Options

Polymer Jacket: PTFE, TFM, PCTFE, other high-performance engineering plastics

Spring: Stainless Steel, Elgiloy, Hastelloy (optional based on medium & application)

Key Advantages

Effectively reduces friction resistance and wear.

Greatly improves sealing performance and service life.

Customizable with anti-pollution fillers in the sealing groove.

Clean, non-contaminating, suitable for LNG and ultra-pure applications.

Low friction coefficient, ensuring smooth operation even at very low speeds.

Maintains low breakaway force after long shutdowns or intermittent use.

Working Conditions

Temperature Range: -50°C to +200°C

Pressure: up to 500 bar

Mediums: LNG, low-temperature ethylene, cryogenic gases, corrosive fluids