Spring Energized Seals for Ball Valves

Spring energized seals for ball valves are advanced sealing solutions designed for rod and dynamic sealing applications in demanding industries such as oil & gas, LNG, and cryogenics. By combining a helical wound spring with a polymer jacket, these seals deliver consistent sealing force, high wear resistance, and reliable performance under extreme conditions where standard polymer seals fail.

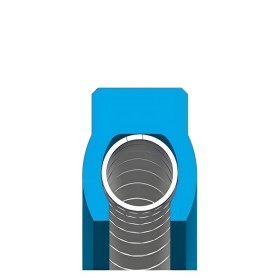

Structure and Materials

Seal Jacket Materials: Virgin PTFE, filled PTFE, UHMW-PE, PEEK

Excellent chemical resistance and thermal stability

Low friction coefficient, ensuring smooth operation

Long-term dimensional stability under extreme pressures and temperatures

Spring Energizer Materials: Stainless Steel, Elgiloy, Hastelloy

Provides uniform sealing load across varying temperatures and pressures

High fatigue resistance, suitable for cryogenic and corrosive environments

Lip Profile Design:

Rounded lip profile for easier installation

Available in a wide range of cross-sections and diameters

Can be customized to fit closed grooves and special cavity geometries

Key Considerations for Selection

When determining whether to use standard polymer seals or spring energized seals, the following factors must be evaluated:

Temperature (maximum/minimum operating range)

Working pressure (system operating and peak pressure)

Speed (dynamic sealing movement)

Medium compatibility (especially with corrosive fluids and gases)

Friction and wear requirements

Environmental factors (abrasion, cryogenic conditions, vacuum)

Equipment application and operational cycles

Sealing cavity structure and groove design

Advantages

Material compound passed API 6A FF/HH Immersion Testing

High-load helical wound spring with small deflection range

Small elastic deformation, suitable for closed grooves

Rounded lip profile enables easy assembly

Wide range of cross-sections and diameters available

NACE-approved energizers for oil and gas service

Working Conditions

Temperature range: –50℃ to +200℃

Pressure ratings: 150LB, 300LB, 600LB, 900LB, 1500LB, 2500LB

Mediums: Gas, water, LNG, hydrocarbons

Applications

Ball valve rod seals

Cryogenic valves and pumps

Oil & gas exploration equipment

LNG transfer systems

High-pressure industrial valves