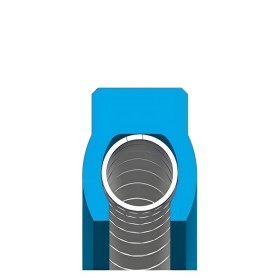

Spring Energized Seals for LNG Nozzles

Spring Energized Seals for LNG Nozzles are high-performance cryogenic sealing solutions designed for LNG fueling systems.

In practice, they are also widely known as LNG Lip Seals for Filling Guns, since they are commonly used in LNG filling guns and nozzles to ensure safe, reliable, and leak-free fueling operations at ultra-low temperatures.

The seal consists of a high-grade polymer jacket combined with a heat-treated Elgiloy® alloy spring. The spring provides continuous radial force, ensuring effective sealing even under low temperatures, low pressures, or sub-optimal surface finishes. Compared with traditional rubber seals, spring energized seals prevent softening, expansion, and wear, significantly extending service life.

Product Detail

Spring Energized Seals for LNG Nozzles / LNG Lip Seals for Filling Guns

- Main Material: Imported cryogenic-grade polymer materials (PTFE, TFM, or PCTFE). Reinforced for ultra-low temperature environments, with a specially ground sealing lip that provides excellent wear resistance and long service life.

- Spring: Heat-treated Elgiloy® alloy spring. Compared with conventional stainless steel, Elgiloy maintains stable properties in cryogenic systems, with high spring load for reliable sealing. Suitable for both static and slow dynamic sealing applications.

Advantages

- Mature spring yield strength improvement process.

- Fatigue test ≥ 2000 cycles (tested under liquid nitrogen conditions).

- Excellent static and dynamic sealing performance.

- Outstanding chemical resistance to LNG and cryogenic media.

- Low friction coefficient, self-lubricating, and excellent dry running properties.

- Anti-aging, no permanent elastic deformation.

- Greatly improved sealing capacity and service life compared to rubber seals.

Working Conditions

- Temperature Range: –100℃ ~ +121℃

- Pressure Ratings: 150LB, 300LB, 600LB, 900LB, 1500LB, 2500LB

- Applicable Mediums: LNG, low temperature ethylene, and other cryogenic fluids