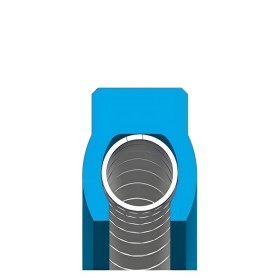

High-Pressure Lip Seals for Ball Valves

High-pressure lip seals are precision-engineered sealing solutions designed for ball valve stem sealing under demanding conditions. By combining a canted coil spring with a high-performance polymer jacket, these seals provide consistent sealing force, excellent wear resistance, and reliable performance in cryogenic, high-pressure, and chemically aggressive environments.

Structure and Materials

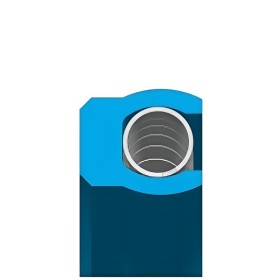

Seal Jacket Materials: Virgin PTFE, TFM, PCTFE, PEEK

Excellent chemical resistance and thermal stability.

Low friction, suitable for dynamic sealing applications.

Long service life compared to conventional elastomers.

Spring Energizer Materials: Stainless Steel (301/304/316), Elgiloy, Hastelloy, Inconel

Provides constant sealing load across a wide range of temperatures and pressures.

Canted coil design ensures high spring load with small deflection range.

Optional Anti-Extrusion Ring:

Required when pressure exceeds 900 LBS, preventing extrusion damage to the sealing lip.

Multifunctional Design:

Integrates two seals and a guide bearing into a single component.

Bi-directional sealing for medium temperature and pressure.

Can also act as a floating piston when designed without an inner diameter.

Performance and Applications

Suitable for static, reciprocating, and rotary sealing.

Recommended for ball valve stem seals, floating pistons, and dynamic sealing in LNG and oil & gas equipment.

Provides reliable sealing in cryogenic, high-pressure, and high-cycle applications.

Advantages

Material compound passed API 6A FF/HH Immersion Testing.

High-load canted coil spring with small deflection range.

NACE-approved energizers for oil & gas applications.

Quick assembly and replacement design, reducing maintenance time.

Superior sealing performance under thermal cycling and high-pressure fluctuations.

Working Conditions

Temperature range: –50℃ to +200℃

Pressure ratings: 150LB, 300LB, 600LB, 900LB, 1500LB, 2500LB

Mediums: LNG, low-temperature ethylene, hydrocarbons, industrial gases

Applications

High-pressure ball valve stem seals

LNG fueling and transfer systems

Cryogenic valves and pumps

Oil & gas pipeline ball valves

Petrochemical and chemical processing equipment