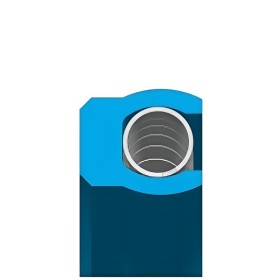

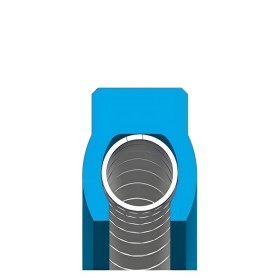

API 6D Piston Seals for Ball Valves

API 6D piston seals are designed to provide long-term, reliable sealing performance in demanding ball valve applications. By combining a helical wound spring with a high-performance polymer jacket, these seals deliver consistent sealing force, chemical resistance, and stability under extreme temperature and pressure conditions.

Structure and Materials

Seal Jacket Materials: Virgin PTFE, filled PTFE, UHMW-PE, PEEK.

These polymers offer superior chemical and heat resistance compared with elastomers.

They are compatible with most chemical fluids, solvents, hydraulic oils, and lubricating oils.

Their low thermal expansion ensures long-lasting sealing performance.

Spring Energizer: Helical wound spring.

Available in Stainless Steel, Elgiloy, and Hastelloy.

The spring overcomes the limited elasticity of PTFE, UHMW-PE, and PEEK, providing constant load compensation even under wear, shrinkage, or tolerance variations.

Optional Anti-Extrusion Ring:

Required when pressure exceeds 900 LBS, protecting the sealing lip from extrusion damage.

Performance and Applications

Designed for both static and dynamic sealing (reciprocating or rotating).

Service Temperature: –196℃ to +300℃

Pressure Range: Vacuum to ultra-high pressure 70 MPa

Speed Capability: Up to 20 m/s

This makes API 6D piston seals an excellent choice for high-temperature corrosive fluids, low-temperature cryogenics, and critical sealing applications in oil & gas.

Advantages

API 6A FF/HH Immersion Tested – validated material reliability.

High-load helical spring with small deflection range.

Compatible with closed grooves due to minimal elastic deformation.

Rigid spring acts as energizer to resist low-temperature shrinkage.

NACE-approved energizers available for oil & gas environments.

Working Conditions

Temperature range: –50℃ to +200℃

Pressure ratings: 150LB, 300LB, 600LB, 900LB, 1500LB, 2500LB

Mediums: Gas, water, hydrocarbons, chemicals

Applications

API 6D certified ball valves

Oil & gas pipelines and processing plants

LNG systems and cryogenic equipment

Petrochemical refineries

High-pressure chemical processing valves