Elgiloy Spring Seals for Cryogenic Ball Valves

In LNG operations, cryogenic ball valves must withstand extreme service conditions, including temperatures as low as –320°F (–196°C) and pressures above 750 psi. These valves are also exposed to repeated thermal cycling, which causes expansion, shrinkage, and additional material stresses. Such harsh environments make achieving reliable, long-term valve sealing an engineering challenge.

Why Elgiloy Spring Seals?

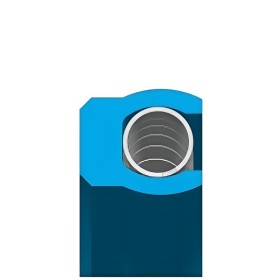

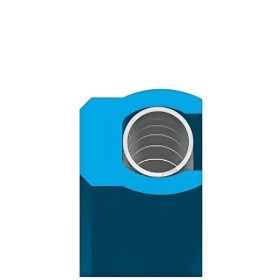

LNG is highly flammable, explosive, and prone to rapid expansion. To minimize accident risks and enhance LNG ball valve safety, sealing systems must meet strict performance requirements. Traditional sealing designs often fall short in cryogenic environments. Research and field applications have shown that the lip seal structure, energized by an Elgiloy spring, provides superior sealing for critical valve components such as:

- Valve stem

- Valve seat

- Body cover

The lip seal design enables a piston-effect valve seat, improving sealing performance while also providing overpressure relief during LNG vaporization. This ensures both safety and long-term reliability in LNG service.

Key Sealing Success Factors

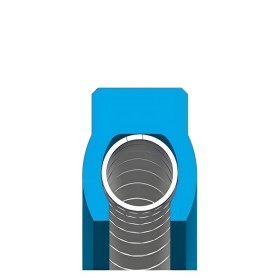

For cryogenic ball valves, effective sealing requires:

- Jacket material that resists thermal cycling and low-temperature embrittlement

- Spring energizer to compensate for material shrinkage

- Anti-extrusion lip geometry for stability under high pressure

At JST, we recommend TMF as the jacket material combined with a Golden Elgiloy helical spring as the energizer. For applications above 900 LB, an anti-extrusion ring is essential. With optimized material selection and structural design, Elgiloy spring seals outperform traditional sealing technologies in cryogenic LNG service.

Advantages of Elgiloy Spring Seals

- API 6A FF/HH immersion-tested compounds

- Passed BS6364 cryogenic performance test (–196℃)

- High-load helical wound Elgiloy spring with minimal deflection range

- Rigid spring maintains sealing force under low-temperature shrinkage

- NACE-approved energizers for oil & gas applications

- Available in one-way or two-way designs

- Configurable with single or double spring designs for critical sealing zones

Working Conditions

- Temperature range: –196℃ to +100℃

- Pressure classes: 150 LB, 300 LB, 600 LB, 900 LB, 1500 LB, 2500 LB

- Mediums: LNG, low-temperature ethylene, cryogenic gases

Application Areas

- Elgiloy spring seals are proven in a wide range of cryogenic and LNG applications, including:

- LNG compressors

- Cryogenic ball valve seat & stem seals

- Cryogenic butterfly valve seat seals

- LNG transfer pumps

- Rocket propulsion fueling systems

- LNG fueling stations

- Petroleum and natural gas equipment

- Specialty gas manufacturing

- Scientific instrumentation