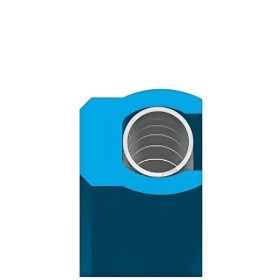

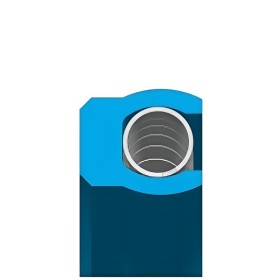

Helical Spring Seals for Oil & Gas Applications

Helical Spring Energized Seals are advanced sealing solutions designed to withstand the harsh conditions of oil and gas operations, including cryogenic temperatures, high pressures, and corrosive media.

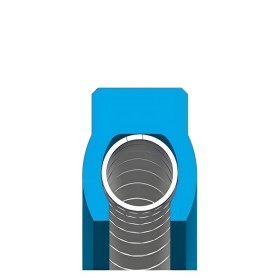

The low-temperature PTFE spring energized seal is typically used as a single piston seal for valves. When the working pressure is ≥1500LB, a high-strength backup ring can be added to protect the sealing lip from extrusion or damage.

Constructed from PTFE + Helical Elgiloy® Spring, these seals can be customized with different polymer and spring materials to suit various temperature and pressure requirements. They are widely used in API 6D ball valves for ultra-low temperature (–196℃) and normal temperature sealing applications.

Product Detail

Helical Spring Energized Seals for Oil and Gas

- Structure: PTFE jacket with helical wound spring energizer.

- Customization: One-way or two-way designs available, with optional single or double spring configurations.

- Backup Protection: High-strength anti-extrusion rings can be added for extreme high-pressure conditions (≥1500LB).

- Applications: Oil and gas valves, LNG cryogenic service, compressor systems, and vacuum sealing.

Advantages

- Material compounds tested and approved under API 6A FF/HH Immersion Testing.

- Successfully passed BS6364 Cryogenic Test (–196℃).

- High-load helical wound spring with small deflection range for stable sealing force.

- Rigid spring acts as energizer to resist low-temperature shrinkage.

- NACE-approved spring energizers available for sour gas and oilfield use.

- One-way or two-way design options for flexible sealing needs.

- Available in single or double spring design for enhanced durability.

Working Conditions

Material:

- Sealing Ring: PTFE + Carbon Fiber

- Spring: 316 Stainless Steel or Elgiloy® (optional)

Temperature Range: –196℃ ~ +100℃

Pressure Ratings: 150LB, 300LB, 600LB, 900LB, 1500LB, 2500LB

Applicable Mediums: LNG, low-temperature ethylene, gas, vacuum, oilfield fluids