Cryogenic Ball Valve Seat Seals for LNG Systems

Cryogenic ball valves are widely used in LNG systems, where extreme low temperatures, high pressures, and aggressive media place unique demands on sealing performance. A critical component of these valves is the cryogenic ball valve seat seal, which ensures reliable tightness and safety during operation.

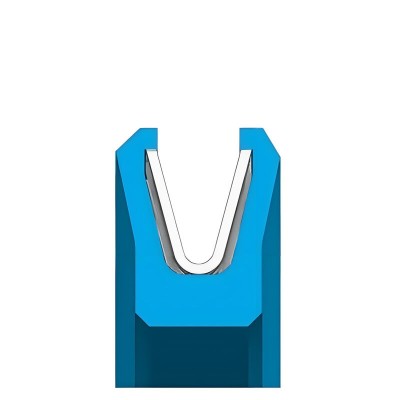

Structure and Design

The seat seal is typically designed with a canted coil spring (or canted level spring) combined with a polymer jacket. This construction delivers both elasticity and resilience at cryogenic temperatures:

- Spring element: provides constant radial or axial load to maintain sealing integrity despite thermal cycling or pressure fluctuations.

- Polymer jacket: offers chemical resistance and low-temperature performance while minimizing friction and wear.

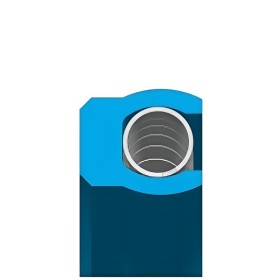

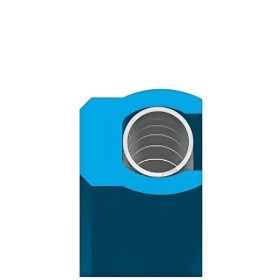

For 6D ball valves, the seal is mainly applied to the single-piston valve seat.

- Temperature range: –50℃ to +260℃

- Pressure rating: up to 2500 LB

When the reverse cavity pressure exceeds 1.33× the rated pressure, a support ring is required to protect the sealing lip. For ratings above 1500 LB, an additional back-up ring is recommended to enhance stability.

Customization for LNG Applications

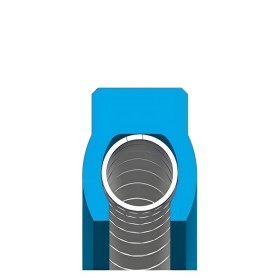

To adapt to different operating conditions, the seat seal can be engineered with modifications, such as:

- Changing the polymer jacket material (e.g., PTFE, modified PTFE, PEEK, UPE)

- Using different spring technologies (canted coil, helical, cantilever)

- Adding T-shaped covers or gaskets

- Incorporating support or back-up rings for extreme pressure conditions

This flexibility ensures reliable sealing even under severe LNG cryogenic environments.

Advantages

- API 6A FF/HH certified material compounds (immersion tested for durability)

- High-load canted coil spring with minimal deflection for consistent sealing force

- NACE-approved energizers for oil & gas applications

- Long service life under cryogenic cycling and fluctuating cavity pressures

- Optimized sealing lip protection with optional support and back-up rings

Working Conditions

- Temperature range: –50℃ ~ +180℃

- Pressure ratings: 150 LB, 300 LB, 600 LB, 900 LB, 1500 LB, 2500 LB

- Mediums: LNG, cryogenic ethylene, and other low-temperature fluids

Applications

- LNG storage and transfer systems

- Cryogenic ethylene pipelines

- Natural gas processing plants

- Low-temperature petrochemical valves