Metal-Faced PTFE Spring Seals Manufacturer

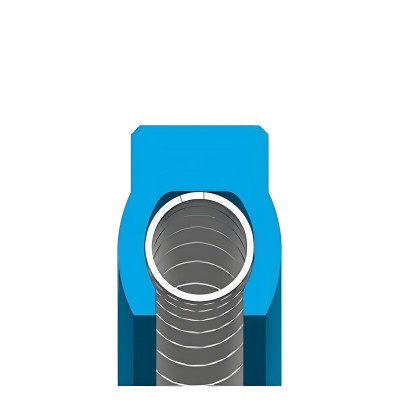

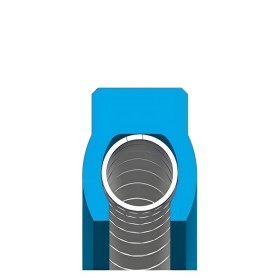

Metal-Faced PTFE Spring Seals are advanced static sealing solutions that combine the strength of a helical wound spring with the chemical resistance of PTFE-based polymers. This unique design ensures reliable performance in extreme cryogenic, chemical, and low-pressure applications.

The helical spring energized static face seal uses a spiral spring with an arc-shaped lip profile. The sealing force is generated both by the internal system pressure and the continuous radial load of the spring. This dual mechanism ensures excellent sealing efficiency, even at ultra-low temperatures and fluctuating pressures.

Product Detail

Metal-Faced PTFE Spring Seals

- Helical Spring Design: Provides a high-load stainless steel spring force, ensuring tight radial sealing for shafts and pistons in low-temperature propellant systems.

- Material Combination: Polymer jacket reinforced with carbon fiber PTFE, combined with a 316 stainless steel spring for superior durability.

- Application Versatility: Ideal for static flange sealing in cryogenic, chemical, and gas service environments.

Advantages

- Successfully passed BS6364 Cryogenic Test (–196℃).

- High-load helical wound spring with optimized deflection range.

- Compact structure, can be installed in standard O-ring grooves.

- Excellent resistance to chemical corrosion and thermal degradation.

- Significantly improves sealing performance and extends service life.

- Low friction coefficient, smooth operation even under low-speed conditions.

Working Conditions

Material:

- Sealing Ring: PTFE + Carbon Fiber

- Spring: 316 Stainless Steel

Temperature Range: –100℃ ~ +180℃

Pressure Ratings: 150LB, 300LB, 600LB, 900LB, 1500LB, 2500LB

Applicable Mediums: LNG, low-temperature ethylene, cryogenic fluids, chemical gases