Home

Подкатегории

О-кольца

Уплотнительные кольца — это универсальные уплотнения, используемые в широком спектре гидравлических и пневматических систем. Они устанавливаются в канавки и сжимаются при сборке для образования плотного уплотнения. Изготовленные из таких материалов, как NBR, FKM, EPDM и силикон, уплотнительные кольца обеспечивают превосходную устойчивость к давлению, температуре и химическим веществам. Эти уплотнения широко используются в клапанах, насосах, цилиндрах, соединителях и фланцах в таких отраслях, как автомобильная промышленность, машиностроение и управление жидкостями. Правильный выбор материала обеспечивает долгосрочную герметизацию и предотвращение утечек.

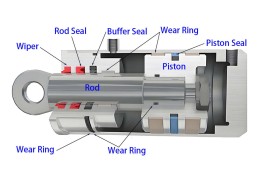

Уплотнения штока

Штоковые уплотнения предотвращают утечку гидравлической жидкости вдоль поршневого штока и поддерживают давление в системе. Изготовленные из материалов NBR, HNBR или PU, они устойчивы к износу, давлению и гидравлическим жидкостям. Обычно используются в строительной технике и промышленном оборудовании, уменьшают трение и защищают внутренние компоненты, повышая надежность системы и срок службы.

Поршневые уплотнения

Поршневые уплотнения предотвращают утечку жидкости между камерами в гидравлических и пневматических цилиндрах, поддерживая давление и производительность системы. Изготовленные из прочных материалов, таких как NBR, HNBR и PTFE, они устойчивы к износу, нагреву и давлению. Широко используются в строительной технике, промышленной гидравлике и производственных системах для надежной работы.

Rod And Piston Seals

Rod and piston seals are used together in hydraulic cylinders to control fluid flow and seal both the rod and piston areas. These seals help maintain pressure in double-acting cylinders and reduce internal and external leakage. Rod and piston seals are typically made from NBR, PU, HNBR, or PTFE, offering excellent wear and pressure resistance. They are widely applied in construction machinery, mobile hydraulics, and industrial equipment. Choosing the right rod and piston seals ensures stable performance and reduces system failures.

Rotary Seals

Rotary seals are designed to seal components with rotational movement, such as shafts in motors and pumps. They prevent leakage of fluids and block entry of dust or debris. Rotary seals are typically made from materials like NBR, FKM, and PTFE for excellent wear and temperature resistance. These seals are used in hydraulic motors, gearboxes, machine tools, and other rotary equipment. Quality rotary seals improve sealing efficiency, reduce downtime, and extend system life.

Wipers Seals

Wiper seals are installed at the cylinder head to remove contaminants from the piston rod during retraction. They help prevent dirt, water, and debris from entering the system. This reduces seal wear and protects internal components. Wiper seals are made from materials like polyurethane (PU), NBR, or PTFE, offering excellent durability and flexibility. They are widely used in construction equipment, mobile hydraulics, and industrial machinery. High-quality wiper seals improve system reliability and reduce maintenance needs.

Wear Rings

Wear rings are non-metallic guide elements used in hydraulic and pneumatic cylinders. They keep the piston or rod aligned, reducing side loads on seals. Made from materials like phenolic resin, polyester, or PTFE composites, wear rings resist abrasion, high pressure, and temperature. They are used in construction machinery, presses, injection molding machines, and other heavy-duty systems. By preventing metal-to-metal contact, they extend the life of both seals and cylinder components.

Back Up Rings

Back up rings are used alongside O-rings and other soft seals to prevent extrusion in high-pressure sealing environments. Placed in the groove behind the primary seal, they provide additional support and help maintain sealing integrity under pressure. Commonly made from PTFE or other rigid materials, back up rings improve performance in demanding hydraulic and pneumatic systems. They are widely used in valves, cylinders, pumps, and heavy-duty equipment where pressure spikes or large gaps are present.

Guide Elements

Guide elements are used to guide and support the piston and rod inside hydraulic cylinders. They maintain alignment and reduce side forces during movement. This protects seals and prevents metal-to-metal contact. Guide elements are made from PTFE, thermoplastics, or composite materials for low friction and high strength. They are widely used in hydraulic presses, mobile equipment, and industrial automation. Reliable guide elements improve system stability and extend component life.

Spring Energized Rod Seals

Spring energized rod seals combine a polymer sealing element with an internal metal spring to provide constant force against the rod surface. This ensures reliable sealing in dynamic applications, especially where pressure, temperature, or media conditions vary. Made from materials like PTFE, PEEK, or other engineered plastics, spring energized rod seals are used in aerospace, chemical processing, cryogenic systems, and high-pressure hydraulics. They offer excellent resistance to wear, extrusion, and chemical attack while maintaining low friction.

Spring Energized Piston Seals

Spring energized piston seals feature a polymer sealing jacket and an internal spring that applies continuous pressure to maintain contact with the cylinder bore. This ensures tight, low-friction sealing in dynamic conditions. Commonly made from PTFE, PEEK, or other high-performance materials, spring energized piston seals resist wear, chemicals, and extreme temperatures. They are used in aerospace systems, cryogenic equipment, chemical processing, and high-pressure hydraulic cylinders, delivering long-term sealing reliability in demanding environments.

Spring Energized Rotary Seals

Spring energized rotary seals use a metal spring to keep sealing pressure against rotating shafts. They provide consistent sealing even with speed, pressure, or thermal changes. Made from materials like PTFE or PEEK, spring energized rotary seals resist wear, heat, and chemicals. They are used in pumps, compressors, mixers, and rotary joints across industries like aerospace, oil & gas, and chemical processing. These seals offer low friction and long service life in demanding environments.

Spring Energized Inside Face Seals

Spring energized inside face seals apply spring force to press the sealing lip against an internal face. This design ensures axial sealing under pressure or vacuum. Made from materials like PTFE or PEEK, spring energized inside face seals resist chemicals, wear, and temperature changes. They are used in valves, static joints, and low-speed rotary systems, especially in aerospace, chemical, and cryogenic applications. These seals offer reliable, low-leakage performance in tight installation spaces.

Spring Energized Outside Face Seals

Spring energized outside face seals use a spring-loaded sealing lip to press outward against a housing face. This ensures tight axial sealing under pressure or vacuum. Made from PTFE, PEEK, or other high-performance materials, spring energized outside face seals resist chemicals, wear, and extreme temperatures. They are used in static joints, valve bodies, and flanged connections in aerospace, chemical, and industrial systems. These seals offer long-lasting performance in tight or critical sealing areas.

Downhole and Intervention Tools

Downhole and intervention tools seals are designed to withstand high pressure, high temperature, and aggressive well fluids. These seals are made from advanced materials such as FKM, HNBR, AFLAS, and PEEK, offering resistance to sour gas, thermal cycling, and mechanical stress. Downhole and intervention tools seals are used in packers, plugs, logging tools, and coiled tubing systems. They provide long-term sealing performance in drilling, completion, and workover operations, where failure is not an option.

API 6A Wellhead Equipment Seal

API 6A wellhead equipment seals are engineered for use in high-pressure, high-temperature (HPHT) wellhead systems. They comply with API 6A specifications for safety, performance, and material standards. These seals are made from durable elastomers or high-performance polymers like FKM, HNBR, or PEEK. API 6A wellhead equipment seals are used in components such as casing heads, tubing hangers, and valve bodies. They ensure reliable sealing under extreme pressure and corrosive downhole conditions, critical for safe oil and gas production.

Low Temperature LNG Seals

LNG seals are engineered for cryogenic temperatures, often below -160°C, where standard materials fail. These seals are made from PTFE, modified PCTFE, or elastomers specially formulated for low-temperature flexibility and chemical resistance. LNG seals are used in pumps, valves, loading arms, and transfer systems within LNG storage, transport, and processing. They ensure long-term sealing reliability in liquefied natural gas operations, preventing leakage and maintaining system integrity under thermal shock and pressure variations.

Sealing Solutions for the LNG Industry

At XHH Seals, we provide advanced sealing solutions engineered for the extreme demands of the LNG (Liquefied Natural Gas) industry. Our seals deliver reliable, leak-free performance in cryogenic environments, even under severe temperature swings and high-pressure conditions.

Whether used in LNG fueling nozzles, storage tanks, transfer pipelines, pumps, or valves, our products are built to withstand intense thermal cycling, chemical exposure, and mechanical stress. We offer a comprehensive range of materials — including PTFE, PCTFE, PEEK, and cryogenic-grade elastomers — to meet the strict standards of LNG applications.

With a strong focus on safety, durability, and precision, XHH Seals empowers our partners to achieve greater efficiency, reliability, and operational excellence across the entire LNG supply chain.

Совместимые уплотнения для ВЭЖХ

Ищете надежные сменные уплотнения для ваших ВЭЖХ-систем? Мы предлагаем полный ассортимент совместимых уплотнений для насосов ВЭЖХ, разработанных для ведущих брендов, таких как Agilent, Waters, Shimadzu и других. Наши уплотнения обеспечивают высокую химическую стойкость, точную посадку и длительный срок службы – идеально подходят для лабораторий, поставщиков сервисных услуг для приборов и OEM-партнеров.

Товаров: 122.

Heavy-Duty, Double-Acting Wiper

Item NO.: W001

Payment: T/T

Product Origin: China

Shipping Port: Shenzhen

Order(MOQ): 50

PTFE Rotary Rod Seal

Item NO.: S001

Payment: T/T

Product Origin: China

Shipping Port: Shenzhen

Order(MOQ): 50

Vee Packing

Item NO.: V001

Payment: T/T

Product Origin: China

Shipping Port: Shenzhen

Order(MOQ): 50

Поршневое уплотнение Glyd ring

Ступенчатое уплотнение штока

Совместимое поршневое уплотнение для ВЭЖХ-систем Agilent 1050–1260 (P/N 0905-1420)

Уплотнительный пакет для скользящей муфты скважинного оборудования

PTFE bronze 40% 60 Shore D brown Compound

PTFE Bronze 40% (60 Shore D, brown) is a reinforced PTFE compound engineered for demanding mechanical and sealing applications. The addition of 40% finely powdered bronze significantly improves the wear resistance, thermal conductivity, and compressive strength of standard PTFE, while retaining excellent chemical resistance and low friction properties.

This compound is ideal for parts exposed to high loads, dynamic motion, or elevated temperatures, and is widely used in hydraulic systems, rotating equipment, and heavy-duty seals.

FKM-FPM 85 Shore A Brown Rubber Compound

FPM 85 Shore A brown is a premium fluorocarbon rubber compound (commonly known as FKM or Viton®-equivalent) designed for sealing applications requiring high heat, chemical resistance, and long-term durability. The brown color allows for easy material identification in multi-compound systems. With a hardness of 85 Shore A, this compound offers the right balance of rigidity and flexibility, ideal for high-demand static and dynamic seals.