Home

Subcategories

O Rings

O rings are versatile seals used in a wide range of hydraulic and pneumatic systems. They fit into grooves and compress during assembly to form a tight seal. Made from materials like NBR, FKM, EPDM, and silicone, O rings provide excellent resistance to pressure, temperature, and chemicals. These seals are commonly used in valves, pumps, cylinders, connectors, and flanges across industries such as automotive, machinery, and fluid control. Proper material selection ensures long-term sealing performance and leak prevention.

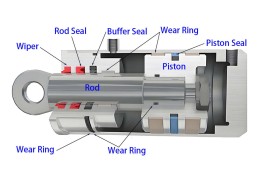

Rod Seals

Rod seals prevent hydraulic fluid leakage along piston rods and maintain system pressure. Made from NBR, HNBR, or PU materials, they resist wear, pressure, and hydraulic fluids. Commonly used in construction equipment and industrial machinery, they reduce friction and protect internal components, improving system reliability and service life.

Piston Seals

Piston seals prevent fluid leakage between chambers in hydraulic and pneumatic cylinders, maintaining pressure and system performance. Made from durable materials like NBR, HNBR, and PTFE, they resist wear, heat, and pressure. Commonly used in construction equipment, industrial hydraulics, and manufacturing systems for reliable operation.

Rod And Piston Seals

Rod and piston seals are used together in hydraulic cylinders to control fluid flow and seal both the rod and piston areas. These seals help maintain pressure in double-acting cylinders and reduce internal and external leakage. Rod and piston seals are typically made from NBR, PU, HNBR, or PTFE, offering excellent wear and pressure resistance. They are widely applied in construction machinery, mobile hydraulics, and industrial equipment. Choosing the right rod and piston seals ensures stable performance and reduces system failures.

Rotary Seals

Rotary seals are designed to seal components with rotational movement, such as shafts in motors and pumps. They prevent leakage of fluids and block entry of dust or debris. Rotary seals are typically made from materials like NBR, FKM, and PTFE for excellent wear and temperature resistance. These seals are used in hydraulic motors, gearboxes, machine tools, and other rotary equipment. Quality rotary seals improve sealing efficiency, reduce downtime, and extend system life.

Wipers Seals

Wiper seals are installed at the cylinder head to remove contaminants from the piston rod during retraction. They help prevent dirt, water, and debris from entering the system. This reduces seal wear and protects internal components. Wiper seals are made from materials like polyurethane (PU), NBR, or PTFE, offering excellent durability and flexibility. They are widely used in construction equipment, mobile hydraulics, and industrial machinery. High-quality wiper seals improve system reliability and reduce maintenance needs.

Wear Rings

Wear rings are non-metallic guide elements used in hydraulic and pneumatic cylinders. They keep the piston or rod aligned, reducing side loads on seals. Made from materials like phenolic resin, polyester, or PTFE composites, wear rings resist abrasion, high pressure, and temperature. They are used in construction machinery, presses, injection molding machines, and other heavy-duty systems. By preventing metal-to-metal contact, they extend the life of both seals and cylinder components.

Back Up Rings

Back up rings are used alongside O-rings and other soft seals to prevent extrusion in high-pressure sealing environments. Placed in the groove behind the primary seal, they provide additional support and help maintain sealing integrity under pressure. Commonly made from PTFE or other rigid materials, back up rings improve performance in demanding hydraulic and pneumatic systems. They are widely used in valves, cylinders, pumps, and heavy-duty equipment where pressure spikes or large gaps are present.

Guide Elements

Guide elements are used to guide and support the piston and rod inside hydraulic cylinders. They maintain alignment and reduce side forces during movement. This protects seals and prevents metal-to-metal contact. Guide elements are made from PTFE, thermoplastics, or composite materials for low friction and high strength. They are widely used in hydraulic presses, mobile equipment, and industrial automation. Reliable guide elements improve system stability and extend component life.

Spring Energized Rod Seals

Spring energized rod seals combine a polymer sealing element with an internal metal spring to provide constant force against the rod surface. This ensures reliable sealing in dynamic applications, especially where pressure, temperature, or media conditions vary. Made from materials like PTFE, PEEK, or other engineered plastics, spring energized rod seals are used in aerospace, chemical processing, cryogenic systems, and high-pressure hydraulics. They offer excellent resistance to wear, extrusion, and chemical attack while maintaining low friction.

Spring Energized Piston Seals

Spring energized piston seals feature a polymer sealing jacket and an internal spring that applies continuous pressure to maintain contact with the cylinder bore. This ensures tight, low-friction sealing in dynamic conditions. Commonly made from PTFE, PEEK, or other high-performance materials, spring energized piston seals resist wear, chemicals, and extreme temperatures. They are used in aerospace systems, cryogenic equipment, chemical processing, and high-pressure hydraulic cylinders, delivering long-term sealing reliability in demanding environments.

Spring Energized Rotary Seals

Spring energized rotary seals use a metal spring to keep sealing pressure against rotating shafts. They provide consistent sealing even with speed, pressure, or thermal changes. Made from materials like PTFE or PEEK, spring energized rotary seals resist wear, heat, and chemicals. They are used in pumps, compressors, mixers, and rotary joints across industries like aerospace, oil & gas, and chemical processing. These seals offer low friction and long service life in demanding environments.

Spring Energized Inside Face Seals

Spring energized inside face seals apply spring force to press the sealing lip against an internal face. This design ensures axial sealing under pressure or vacuum. Made from materials like PTFE or PEEK, spring energized inside face seals resist chemicals, wear, and temperature changes. They are used in valves, static joints, and low-speed rotary systems, especially in aerospace, chemical, and cryogenic applications. These seals offer reliable, low-leakage performance in tight installation spaces.

Spring Energized Outside Face Seals

Spring energized outside face seals use a spring-loaded sealing lip to press outward against a housing face. This ensures tight axial sealing under pressure or vacuum. Made from PTFE, PEEK, or other high-performance materials, spring energized outside face seals resist chemicals, wear, and extreme temperatures. They are used in static joints, valve bodies, and flanged connections in aerospace, chemical, and industrial systems. These seals offer long-lasting performance in tight or critical sealing areas.

Downhole and Intervention Tools

Downhole and intervention tools seals are designed to withstand high pressure, high temperature, and aggressive well fluids. These seals are made from advanced materials such as FKM, HNBR, AFLAS, and PEEK, offering resistance to sour gas, thermal cycling, and mechanical stress. Downhole and intervention tools seals are used in packers, plugs, logging tools, and coiled tubing systems. They provide long-term sealing performance in drilling, completion, and workover operations, where failure is not an option.

API 6A Wellhead Equipment Seal

API 6A wellhead equipment seals are engineered for use in high-pressure, high-temperature (HPHT) wellhead systems. They comply with API 6A specifications for safety, performance, and material standards. These seals are made from durable elastomers or high-performance polymers like FKM, HNBR, or PEEK. API 6A wellhead equipment seals are used in components such as casing heads, tubing hangers, and valve bodies. They ensure reliable sealing under extreme pressure and corrosive downhole conditions, critical for safe oil and gas production.

Low Temperature LNG Seals

LNG seals are engineered for cryogenic temperatures, often below -160°C, where standard materials fail. These seals are made from PTFE, modified PCTFE, or elastomers specially formulated for low-temperature flexibility and chemical resistance. LNG seals are used in pumps, valves, loading arms, and transfer systems within LNG storage, transport, and processing. They ensure long-term sealing reliability in liquefied natural gas operations, preventing leakage and maintaining system integrity under thermal shock and pressure variations.

Sealing Solutions for the LNG Industry

At XHH Seals, we provide advanced sealing solutions engineered for the extreme demands of the LNG (Liquefied Natural Gas) industry. Our seals deliver reliable, leak-free performance in cryogenic environments, even under severe temperature swings and high-pressure conditions.

Whether used in LNG fueling nozzles, storage tanks, transfer pipelines, pumps, or valves, our products are built to withstand intense thermal cycling, chemical exposure, and mechanical stress. We offer a comprehensive range of materials — including PTFE, PCTFE, PEEK, and cryogenic-grade elastomers — to meet the strict standards of LNG applications.

With a strong focus on safety, durability, and precision, XHH Seals empowers our partners to achieve greater efficiency, reliability, and operational excellence across the entire LNG supply chain.

Coal Mine Hydraulic Support Sealing System

Our Coal Mine Hydraulic Support Sealing System is specifically designed for the demanding underground mining environment. These high-performance seals ensure reliable operation of hydraulic jacks, cylinders, and support systems under high pressure, heavy load, and exposure to water-based emulsions. We offer a full range of piston seals, rod seals, wear rings, and dust wipers—engineered to extend service life and reduce maintenance downtime.

Compatible HPLC Seals

Looking for reliable replacement seals for your HPLC systems? We offer a full range of compatible HPLC pump seals designed to fit leading brands like Agilent, Waters, Shimadzu, and more. Our seals deliver high chemical resistance, precise fitment, and long service life—ideal for laboratories, instrument service providers, and OEM partners.

API 6D Ball Valve & LNG Seal Solutions

XHH Seals provides high-performance sealing solutions for API 6D ball valves and LNG equipment. Our seals are engineered to withstand extreme pressure, cryogenic temperatures, and corrosive media. With advanced spring-energized PTFE, Elgiloy, and metal-faced designs, we help customers achieve reliable sealing performance in demanding oil, gas, and liquefied natural gas applications.

There are 122 products.

Rod U cup seal

Cryogenic PTFE Spring Energized Seals

Constructed with a helical wound spring and a PTFE-based polymer jacket, these seals are primarily used as flange internal face seals in cryogenic devices. Compared with traditional O-rings, spring energized seals deliver superior friction control, dimensional stability, and extended wear life, ensuring a long-lasting and leak-free seal even under deep cryogenic conditions.

They are widely applied in valve flange connections, cryogenic piping systems, and LNG equipment where leakage prevention is essential.

Piston Seals Compatible with Agilent 1090 – Replaces 5062-2494

01-0022-00 Compatible Vac Boot .120"/3.0mm ID Olive for Asymtek Dispensing Equipment

PTFE D05 pigment 57 Shore D turquoise Compound

Homag 4012020065 / 4-012-02-0065 O-Ring – Replacement Seal for KL, KFL, Ambition Series

Polyester Resin Guide Strip / Tape

Replacement Seal for Nordson 273139 | Compatible Hot Melt Pump Seal

High-quality seals

Compatible with series: Nordson®

P/N:273139

P/N:1047747

Snap In Single Lip Wiper2

OD Dynamic Seal

Single Acting Heavy-Duty Piston Seal

Double Lipped Rod U Cup Seal

Available in both standard and custom sizes, this versatile seal is machined or molded from high-grade materials to meet the demands of modern hydraulic systems.