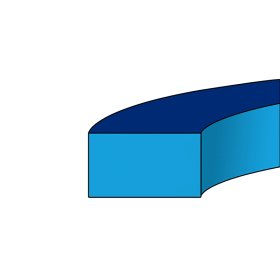

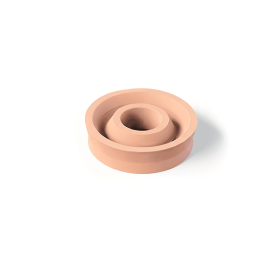

PTFE bronze 40% 60 Shore D brown Compound

High-Strength Bronze-Filled PTFE for Load-Bearing and Wear-Resistant Sealing

PTFE Bronze 40% (60 Shore D, brown) is a reinforced PTFE compound engineered for demanding mechanical and sealing applications. The addition of 40% finely powdered bronze significantly improves the wear resistance, thermal conductivity, and compressive strength of standard PTFE, while retaining excellent chemical resistance and low friction properties.

This compound is ideal for parts exposed to high loads, dynamic motion, or elevated temperatures, and is widely used in hydraulic systems, rotating equipment, and heavy-duty seals.

Technical Specifications

PTFE bronze 40% 58 Shore D brown

Mechanical

| Mechanical properties | Standard | Unit | Data-Moulded |

| Density | ASTM D792 | g/cm³ | 2,98-3,16 |

| Hardness-Shore D | ASTM D2240 | / | ≥ 58 |

| Tensile Strength-CD* | ISO 527 | N/m㎡ | ≥ 20 |

| Elongation at Break-CD* | ISO 527 | % | ≥ 220 |

| Compressive Strength at 1% Deformation -CD* | ASTM D695 | N/m㎡ | 8 |

Deformation under Load at Room Temperature After 24 Hours at 13,7 N/m㎡- CD* | ASTM D621 | % | ≤ 8 |

Permanent Deformation Under Load After 24 Hours of Rest at Room Temperature -CD* | ASTM D621 | % | ≤ 5 |

Thermal

| Thermal properties | Standard | Unit | Data-Moulded |

| Service Temperature (Min-Max) | / | ℃ | -200/+260 |

| Thermal Expansion Coefficient (Linear) 25 -100℃ | Similar to ASTM D696 | 10-5 (mm/mm)/℃ | 8 -11 |

Electrical

| Electrical properties | Standard | Unit | Data-Moulded |

| Surface Resistivity | ASTM D257 | Ω | 1012 |

Tribological

| Tribological properties | Standard | Unit | Data-Moulded |

| Dynamic Coefficient of Friction | ASTM D1894 ASTM D3702 | / | 0,15-0,25 |

| Wear Factor K | ASTM D3702 | / | 0,01-0,03 |

*CD=Cross Direction

feedback Report comment