Search in blog

Blog categories

- Пружинные уплотнения (9)

- Уплотнения для систем горячего расплава (18)

- Скважинные и интервенционные инструменты (3)

- Решения для герметизации в индустрии СПГ (4)

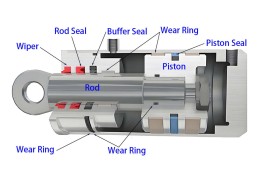

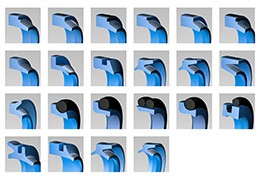

- Уплотнения гидравлических цилиндров (6)

- ПТФЭ (3)

- О-кольца (6)

- Износостойкие кольца (2)

- FKM (2)

- FFKM (5)

- комплект уплотнений Nordson (13)

- Справочник производителей и поставщиков уплотнительных колец (1)

- Сальник (1)

- Деревообработка Уплотнительные детали (1)

- горнодобыча (1)

- Системы дозирования (10)

- (3)

- (1)

- (1)

- (1)

- (3)

- (1)

- (1)

- (2)

- (1)

- (1)