What Is Well Packing? Fracturing Pump Sealing Guide by XHH Seals

The Role of Well Packing in Hydraulic Fracturing

Hydraulic fracturing, or pressure pumping, is a well stimulation method used to extract oil and gas from tight formations such as shale and sandstone. In this process, a high-pressure pump—commonly known as a fracturing pump—injects a slurry mixture of water, chemicals, and proppants (sand or ceramics) into the reservoir to create fractures that release hydrocarbons.

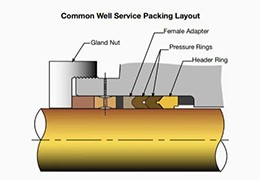

At the heart of the pump’s fluid end, which handles this high-pressure slurry, lies a critical component: well service packing (also known as well packing or fracturing pump packing). This component ensures a tight seal and prevents leakage during continuous high-pressure pumping operations.

How Does Well Service Packing Work?

Well service packing (WSP) serves as both a static and dynamic seal inside the fluid end of a reciprocating fracturing pump:

- The outer diameter of the WSP forms a static seal against the cylinder bore of the fluid end.

- The inner diameter dynamically seals against the pump plunger, which moves back and forth during suction and discharge strokes.

This dual-sealing function prevents high-pressure fracturing fluid—often containing abrasive particles and corrosive chemicals—from escaping the system, ensuring both equipment safety and environmental protection.

Key Challenges in Fracturing Pump Sealing

WSP must endure some of the harshest working environments in the oil and gas industry:

- High operating pressures: Often between 70–110 MPa (10,000–16,000 psi)

- High sand content: Up to 18% proppant slurry

- Acidic or chemically aggressive fluids

- Long-stroke, high-frequency operations

- Extreme temperature fluctuations

Choosing the right fracturing pump packing is essential to avoid equipment failure, unplanned downtime, and excessive maintenance costs.

XHH Seals Solutions for Well Packing

At XHH Seals, we specialize in manufacturing high-performance well packing designed to handle extreme fracturing conditions. Our well service packing is engineered to provide:

- Superior sealing under ultra-high pressure

- Extended wear resistance in abrasive and acidic environments

- Long service life across multiple fracturing layers

- Reduced fluid end and plunger wear

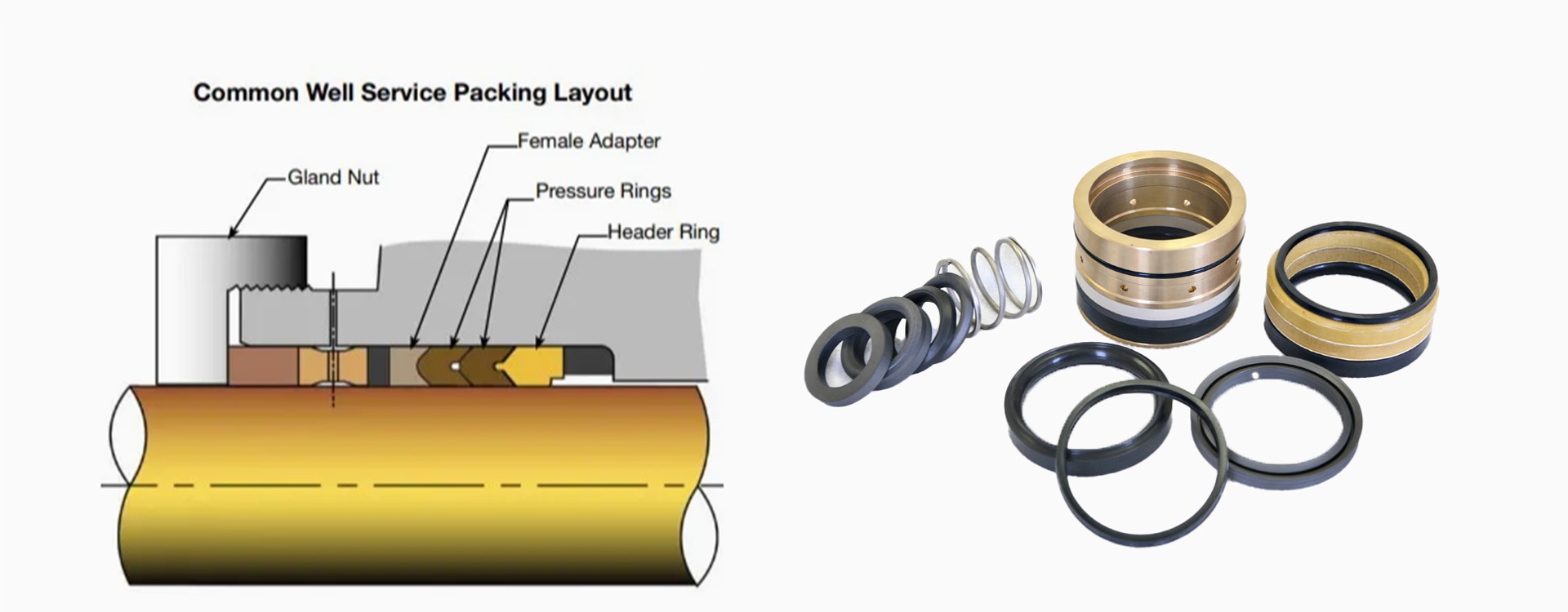

Featured Product: EV Series Well Service Packing

Our EV Series well packing has been tested in field conditions such as shale gas fracturing and has delivered reliable performance:

- Operating Pressure: 70–110 MPa

- Sand Ratio: Up to 10–18%

- Acid Compatibility: Resistant to common fracturing fluids

- Service Life: 50–80 fracturing layers

- Material Options: Advanced polyurethane, fabric-reinforced NBR, FKM, and proprietary elastomers

We also provide custom well packing solutions for valve inserts, optimized for impact resistance and high-cycle durability.

Benefits of Using XHH Seals Well Packing

Choosing XHH Seals for your well packing needs provides significant advantages:

- Longer sealing life, fewer replacements per well

- Lower maintenance and operating costs

- Reduced downtime from fluid end failure

- Compatibility with pumps from major OEMs (e.g. Halliburton, Weir, SPM)

- Environmentally responsible sealing that prevents slurry leakage

Selecting the Right Well Packing for Your Application

When choosing fracturing pump packing, consider the following:

| Parameter | Selection Tip |

|---|---|

| Pump Pressure | Match WSP pressure rating to your max pump output |

| Fluid Type | Choose acid-resistant or chemical-compatible materials |

| Sand Ratio | Use abrasion-resistant materials for >10% proppant |

| Stroke Frequency | For long-stroke/high-cycling systems, use reinforced WSP |

| OEM Compatibility | Ensure sizing matches your pump model (custom options available) |

Frequently Asked Questions (FAQ)

What is the difference between well service packing and standard pump seals?

Well packing is designed specifically for high-pressure, abrasive, and chemically aggressive conditions found in hydraulic fracturing. Standard pump seals may not withstand such environments.

How often should fracturing pump packing be replaced?

Depending on the sand content and pressure, high-performance WSP from XHH Seals can last through 50–80 fracturing stages, significantly reducing replacement frequency.

Is XHH Seals’ WSP compatible with my current pump?

Yes. We offer packing sizes compatible with major pump OEMs like Halliburton, SPM, Weir, and more. Custom sizing is also available.

Can XHH well packing handle acid fracturing?

Absolutely. Our WSP is formulated for acid-resistant performance in aggressive fluid environments.

Contact XHH Seals for Well Service Packing

Looking for a reliable well packing supplier that supports extreme hydraulic fracturing operations?

Email: xhh@xhh-smartech.com

Let us help you reduce downtime, increase productivity, and extend the life of your fracturing equipment.

Deja un comentario