Discover OEM-equivalent TES Teflon® Seals for Nordson melters. and custom-fit for BM200, VD200, DD200, 5506, 5550,...

TES Teflon® Encapsulated Seals – OEM Replacement Plates & Rings for Nordson-Compatible Melters

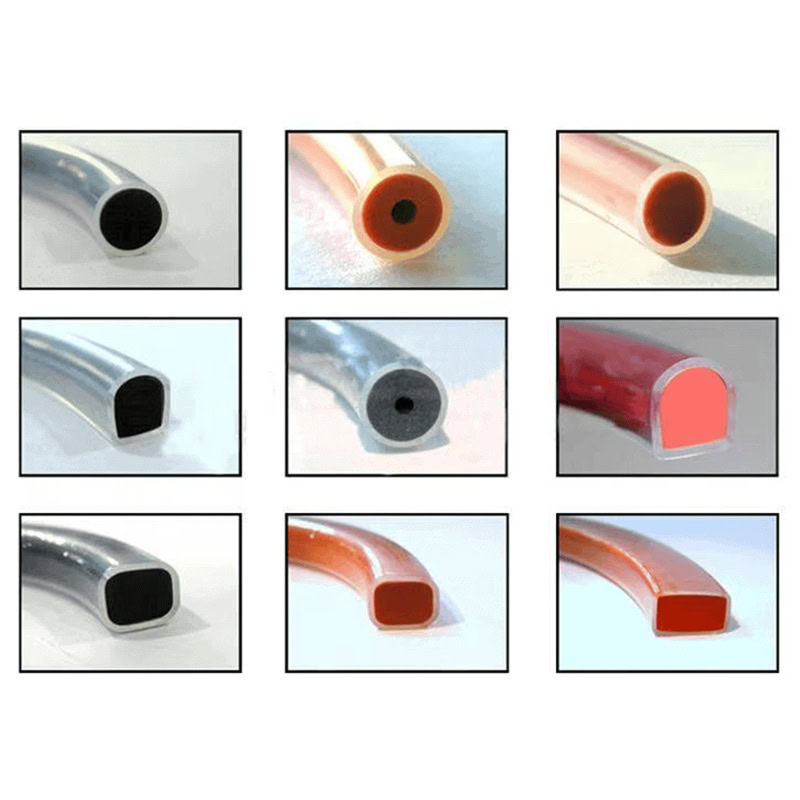

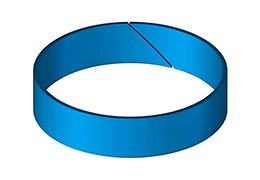

Replacement Teflon® Encapsulated Silicone (TES) plates and ring seals integrate a resilient silicone core with a fluoropolymer (FEP or PFA) Teflon® outer layer to deliver outstanding chemical resistance, high‑temperature stability, and low friction for leak‑free performance in melt‑adhesive equipment. Designed for Nordson roll and barrel melters—including BM200, VD200, DD200, 5506, 5550, Durapail, Versapail, and 506 series—these replacement seals meet exact OEM dimensions and tolerances while offering significant cost savings.

Overview: TES Seals for Compatible with Nordson® Melters

What Are Teflon® Encapsulated Silicone (TES) Seals?

Key Features of TES Seals

Which Nordson Models Are TES Seals Compatible With?

OEM‑Quality & Customization

1. OEM‑Quality Replacement

2. Customization Options

Performance & Cost Comparison

Compatible with OEM and Aftermarket Suppliers

Zentz Industrial

Astro Packaging

Universal Adhesive Systems

Radwell International

Frequently Asked Questions

A: Yes, our TES Plate and Ring Seals are designed to meet the dimensions and performance of Nordson OEM components.

A: Service life depends on temperature, adhesive type, and usage cycles. Under standard operating conditions, users can expect 6–12 months of reliable performance before replacement is needed.

A: We do not recommend reusing TES seals once removed. Their sealing performance may be compromised after thermal cycling or compression set.

A: Custom sizes or materials typically require 10–15 business days, depending on complexity.

Leave a comment