Hydraulic Seals

Subcategories

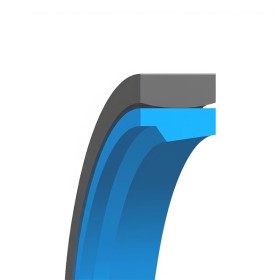

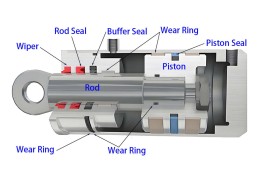

Rod Seals

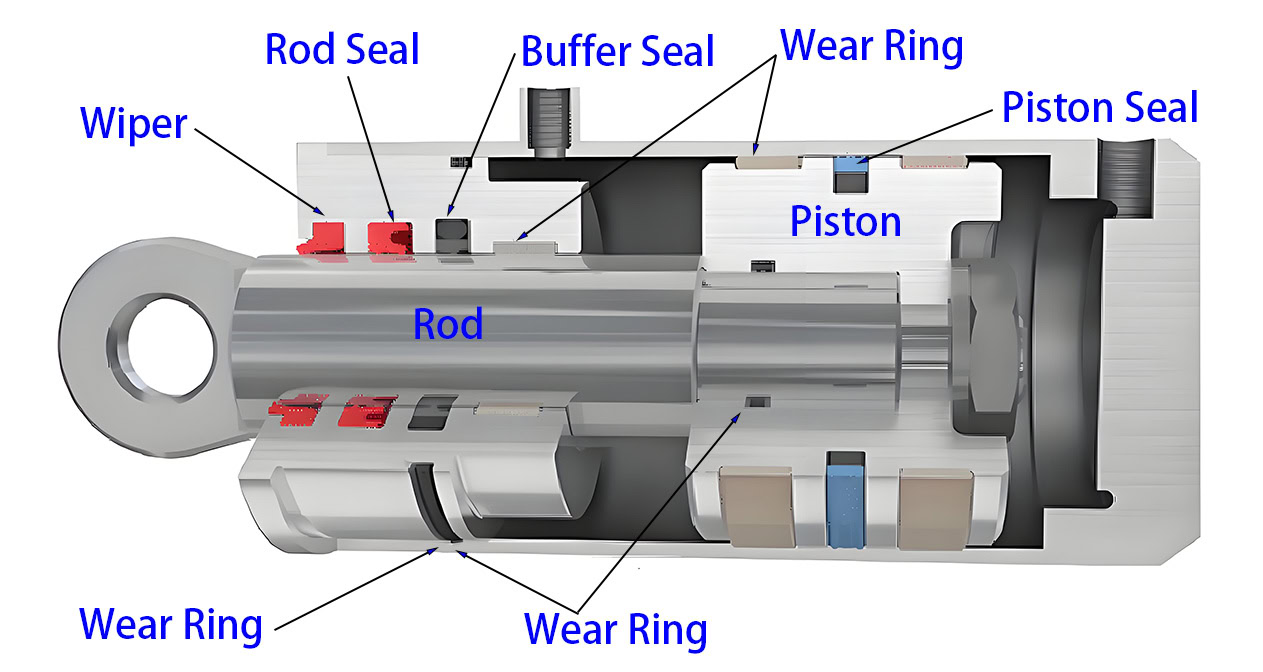

Rod seals are essential components in hydraulic cylinders. They prevent fluid from leaking along the piston rod and help maintain system pressure. Made from materials such as Nitrile Rubber (NBR), Hydrogenated Nitrile (HNBR), and Polyurethane (PU), these seals offer strong resistance to wear, pressure, and hydraulic fluids. Rod seals are commonly used in construction equipment, mobile machinery, and various industrial systems. They help reduce friction and protect internal components from damage. With proper selection and installation, rod seals can improve system reliability and extend service life.

Piston Seals

Piston seals play a key role in hydraulic and pneumatic cylinders. They seal the piston as it moves inside the cylinder bore, blocking fluid from passing between chambers. This helps maintain pressure and control system performance. Piston seals are often made from materials like NBR, HNBR, and PTFE, offering good resistance to wear, heat, and pressure. These seals are widely used in construction machines, industrial hydraulics, and manufacturing equipment. With proper design and fit, piston seals improve reliability and reduce leakage.

Rod And Piston Seals

Rod and piston seals are used together in hydraulic cylinders to control fluid flow and seal both the rod and piston areas. These seals help maintain pressure in double-acting cylinders and reduce internal and external leakage. Rod and piston seals are typically made from NBR, PU, HNBR, or PTFE, offering excellent wear and pressure resistance. They are widely applied in construction machinery, mobile hydraulics, and industrial equipment. Choosing the right rod and piston seals ensures stable performance and reduces system failures.

Guide Elements

Guide elements are used to guide and support the piston and rod inside hydraulic cylinders. They maintain alignment and reduce side forces during movement. This protects seals and prevents metal-to-metal contact. Guide elements are made from PTFE, thermoplastics, or composite materials for low friction and high strength. They are widely used in hydraulic presses, mobile equipment, and industrial automation. Reliable guide elements improve system stability and extend component life.

Rotary Seals

Rotary seals are designed to seal components with rotational movement, such as shafts in motors and pumps. They prevent leakage of fluids and block entry of dust or debris. Rotary seals are typically made from materials like NBR, FKM, and PTFE for excellent wear and temperature resistance. These seals are used in hydraulic motors, gearboxes, machine tools, and other rotary equipment. Quality rotary seals improve sealing efficiency, reduce downtime, and extend system life.

Wipers Seals

Wiper seals are installed at the cylinder head to remove contaminants from the piston rod during retraction. They help prevent dirt, water, and debris from entering the system. This reduces seal wear and protects internal components. Wiper seals are made from materials like polyurethane (PU), NBR, or PTFE, offering excellent durability and flexibility. They are widely used in construction equipment, mobile hydraulics, and industrial machinery. High-quality wiper seals improve system reliability and reduce maintenance needs.

Back Up Rings

Back up rings are used alongside O-rings and other soft seals to prevent extrusion in high-pressure sealing environments. Placed in the groove behind the primary seal, they provide additional support and help maintain sealing integrity under pressure. Commonly made from PTFE or other rigid materials, back up rings improve performance in demanding hydraulic and pneumatic systems. They are widely used in valves, cylinders, pumps, and heavy-duty equipment where pressure spikes or large gaps are present.

O Rings

O rings are versatile seals used in a wide range of hydraulic and pneumatic systems. They fit into grooves and compress during assembly to form a tight seal. Made from materials like NBR, FKM, EPDM, and silicone, O rings provide excellent resistance to pressure, temperature, and chemicals. These seals are commonly used in valves, pumps, cylinders, connectors, and flanges across industries such as automotive, machinery, and fluid control. Proper material selection ensures long-term sealing performance and leak prevention.

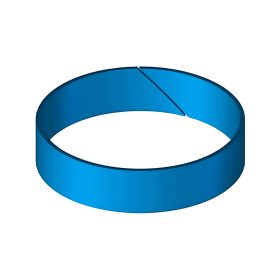

Wear Rings

Wear rings are non-metallic guide elements used in hydraulic and pneumatic cylinders. They keep the piston or rod aligned, reducing side loads on seals. Made from materials like phenolic resin, polyester, or PTFE composites, wear rings resist abrasion, high pressure, and temperature. They are used in construction machinery, presses, injection molding machines, and other heavy-duty systems. By preventing metal-to-metal contact, they extend the life of both seals and cylinder components.

There are 37 products.

Hydraulic Cylinder PTFE Wear Ring

O ring

POM Wear Ring

This wear ring is capable of withstanding high side loads and preventing metal-to-metal contact between the piston and the bore or the rod and the gland.

Item NO.: POM

Payment: T/T

Product Origin: China

Shipping Port: Shenzhen

Order(MOQ): 50

Back Up Rings

The back-up rings come standard in Virgin PTFE but can be made from any filled PTFE compound to increase the pressure capabilities.

PEEK,POM, Nylon back up ring are also made.

Item NO.: BUR

Payment: T/T

Product Origin: China

Shipping Port: Shenzhen

Order(MOQ): 50

Heavy-Duty, Double-Acting Wiper

Item NO.: W001

Payment: T/T

Product Origin: China

Shipping Port: Shenzhen

Order(MOQ): 50

PTFE Rotary Rod Seal

Item NO.: S001

Payment: T/T

Product Origin: China

Shipping Port: Shenzhen

Order(MOQ): 50

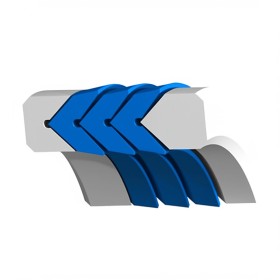

Vee Packing

Item NO.: V001

Payment: T/T

Product Origin: China

Shipping Port: Shenzhen

Order(MOQ): 50

Glyd ring Piston Seal

Item NO.: P001

Payment: T/T

Product Origin: China

Shipping Port: Shenzhen

Order(MOQ): 50

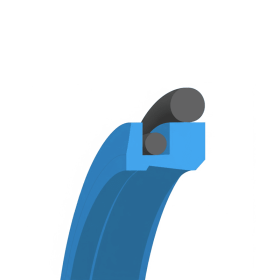

Rod step seal

The Rod step seal is especially suitable for control cylinders, servo systems, machine tools, construction machines, and chemical industry applications.

Different PTFE material sliding rings and rubber material O rings can be selected for different applications to meet different fluid media and temperature ranges.

Encapsulated O-Rings

Phenolic Wear Ring

Heavy-Duty, Double-Acting Wiper PT2

Item NO.: W003

Payment: T/T

Product Origin: China

Shipping Port: Shenzhen

Order(MOQ): 50